Design Guide

Click to download our Installation Guide. A summary follows:

Components

A Paverdeck project is simple to install by a homeowner or contractor with simple skills and tools. The deck is assembled on top of galvanized beams (or red-iron I-beams).

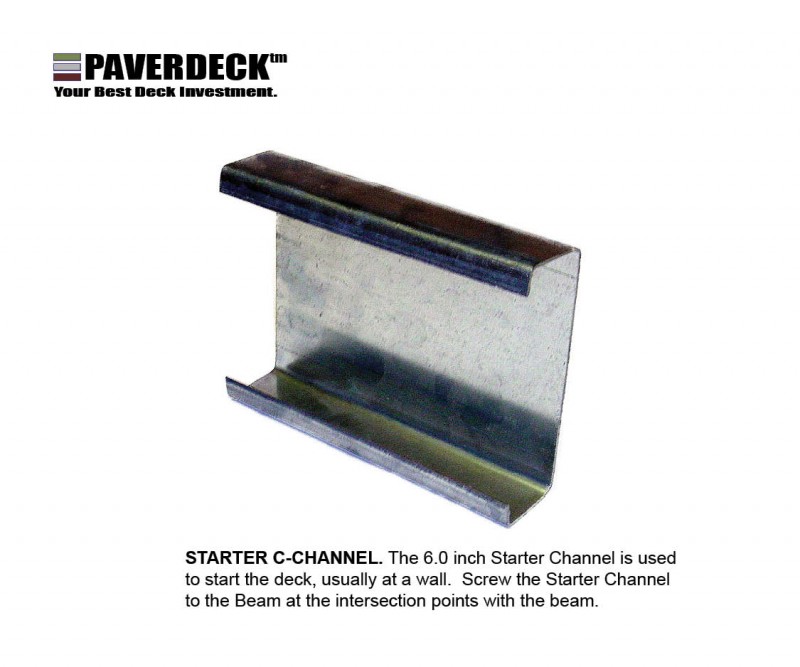

(1) The Starter c-channel is first installed on the beam.

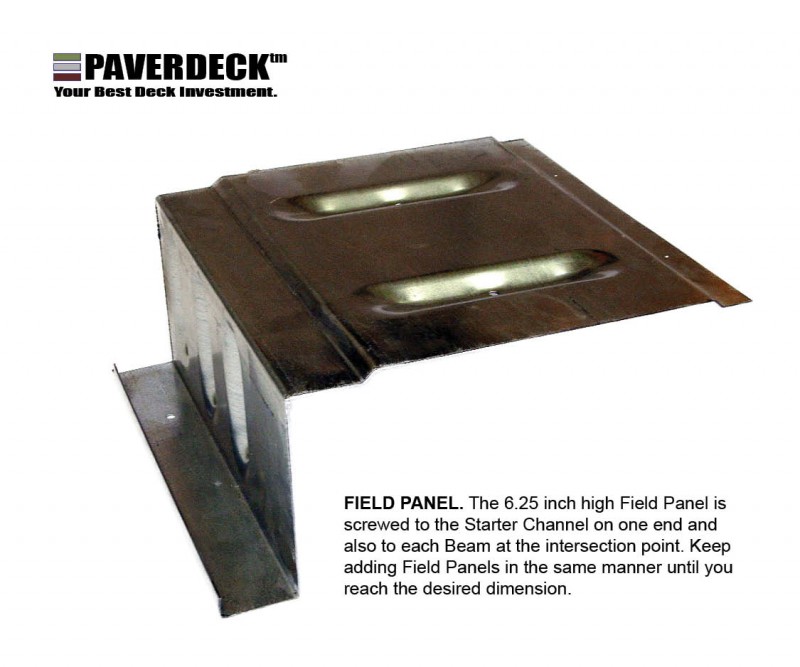

(2) The first Field Panel is then installed on to the Starter.

(3) Keep adding Field Panels until you reach your deck width. Note the Field Panels can be spaced from 10.125-11.0 inches on the preceding shoulder.

(4) Install the End Panel to complete the diaphragm.

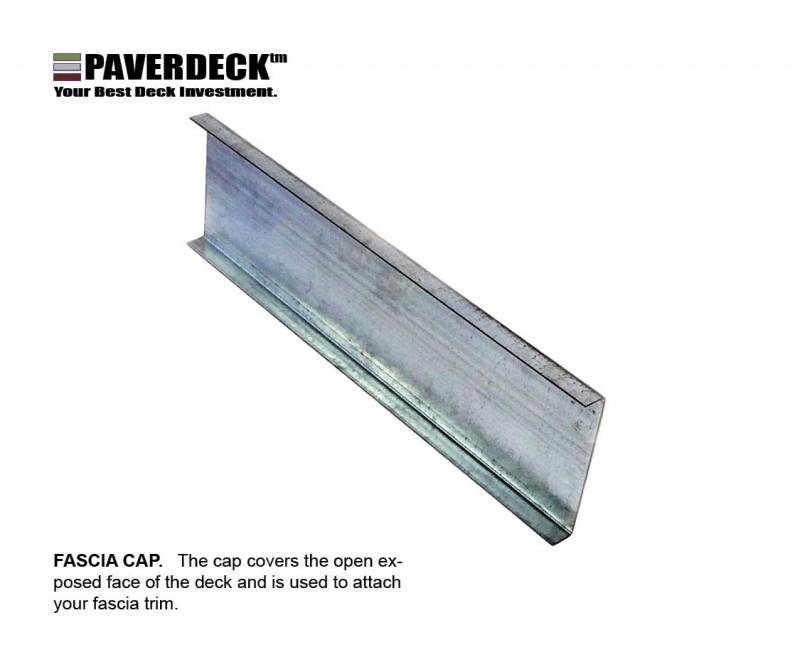

(5) Install Fascia Cap over the open joist ends to support the fascia finish material.

(6) Proceed to glue your stone pavers to the perimeter (leaving 1.5 inches overhang on the steel).

(7) Install your filter fabric, and dry-lay your pavers in the field.

(8) Lock in the field pavers with polymeric sand.

(9) If yu are installing a railing, you will need to install a railing post stiffeners per the guide.

Click to expand the photos.

Design and estimate the cost of your projects

The system can accomodate any design – use the following tips:

Deckpan

- Our deckpan is 6.25-inches in height.

- Deckpan panels come in 10, 12, and 14-ft lengths. Design with dimensions of 5, 6, 7, 10, 12, 14 ft to ensures best use of material.

- The deckpan can span 14-feet from beam to beam (although typical is 12-feet), and can cantilever 39-inches over a beam.

- You can create curved profiles of the deck within the cantilever portion, or greater if you use another beam supporting the curved portion.

- The deck can be attached to a steel ledger at the house (typically an L4x4.25 you purchase locally).

- The deck can also be free-floating on independent beams.

- If you need a deckpan span greater than 14-feet, we can supply you with extra reinforcement to provide for a 16-foot span.

- Calculate your total gross surface area using the dimensions above – then mulitply by the current deckpan pricing.

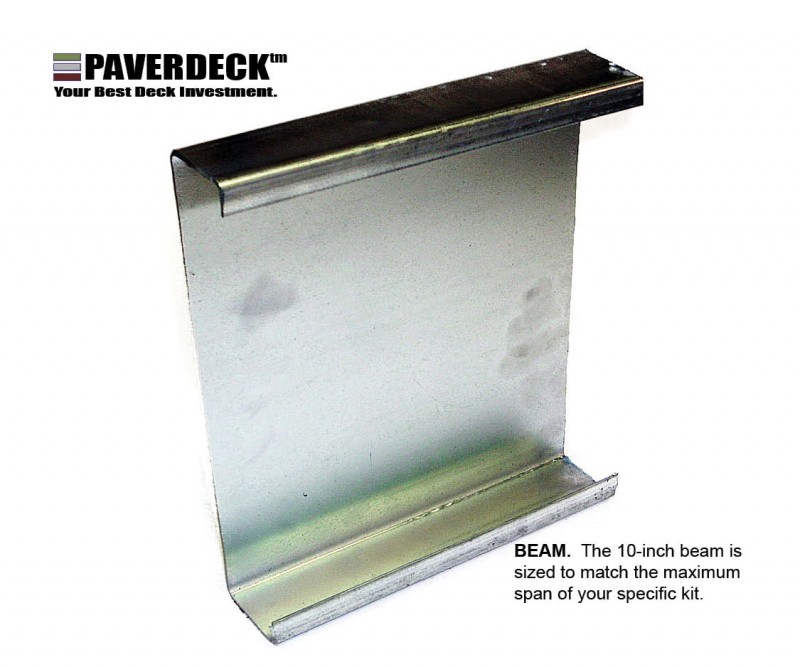

Beams (Optional)

- Our standard 10-inch galvanized steel beam typically spans 10 feet between posts. For greater spans, you can use a red-iron structural beam (e.g. W8x21) that you would purchase from your local supplier.

- Calculate your total linear feet of beams – then mulitply by the current beam pricing.

- Footings (Not supplied. Check with your local building department for local loading conditions).

- Steel helical piles for frost foundations and calculate loading based on 110 psf (although check with your local building department for local loading conditions). Footings are normally spaced maximum 10-feet on the beam.

- Concrete pier columns on a bigfoot-type footing form installed below the frost line. Note your spacing is dictated by soil conditions and is typically 6-8 feet.

You can also float the deck on 2×2 ft concrete deckpads with spacing around 6 feet.

Surface Finish

- The Paverdeck system can support thick pavers up to 3-inches, but note that the thicker the paver, the greater the loading support required by your footings. This would result in larger or more expensive footings. We normally use pavers from 1-inch to 2-inches thick.

Point Loads

- The Paverdeck system can support a hot-tub. Some opt to install extra footings under the hot-tub.

- The Paverdeck can support point loads of approx. 1000 lbs. For concentrated loads, a stiffener should be installed under the point load in ther deckpan, and ideally would align with a footing.